Compression Fitting

Compression Fitting Specification

- Product Type

- Compression Fitting

- Material

- Brass

- Connection

- Threaded

- Thickness

- Standard

- Standard

- DIN, ASTM, JIS

- Technics

- Forged

- Surface Treatment

- Chrome Plated

- Length

- Varies as per specifications

- Wall Thickness

- As per standard

- Nominal Pressure

- PN16

- Color

- Metallic

- Usage

- Pipe Connection

- Corrosion Resistance

- High

- Application

- Plumbing, Gas Fitting, Industrial Piping

- Temperature Range

- -20°C to 150°C

- End Type

- Male/Female

- Working Pressure

- Up to 16 Bar

- Packaging Type

- Box/Carton

- Shape

- Straight

- Size Range

- 1/8" to 2"

- Installation

- Easy to install, requires no soldering

Compression Fitting Trade Information

- Minimum Order Quantity

- 100 Pieces

- Main Domestic Market

- South India

About Compression Fitting

Compression Fitting comprises a nut & ferrule and is intended to be utilized in plumbing systems. It has been made of high grade HDPE polymer for having good structural strength, abrasion resistance, and durability. This fitting is available in different structural configurations including bends, T, and reducers. It is also suitable to be perfect for irrigation & drinking water systems. Compression Fitting shows good pressure bearing ability and can withstand various environmental conditions. It can easily be applied with help of threaded end and assures leak-proof connection.

WE MAINLY DEAL IN SOUTH INDIA

Versatile Application and Superior Performance

Engineered for a range of uses from plumbing and gas connections to industrial piping, these compression fittings deliver exceptional reliability. Suitable for demanding environments, they maintain performance under high pressure (up to 16 Bar) and wide temperature fluctuations (-20C to 150C). Their precision-forged brass construction ensures consistent durability even with frequent installation and removal.

Easy Installation and Secure Connections

Designed to eliminate the need for soldering, these straight compression fittings offer a simple, threaded connection. This makes them user-friendly for both professionals and DIY installers. The shape and standard wall thickness provide a leak-resistant joint, while the chrome plating enhances corrosion protection and maintains a metallic finish.

Compliance and Quality Assurance

Strict adherence to DIN, ASTM, and JIS standards ensures that every fitting meets industry performance and safety requirements. With standardized thickness and nominal pressure ratings, clients can confidently integrate these fittings into existing systems, knowing they meet international quality benchmarks.

FAQs of Compression Fitting:

Q: How do you install a straight compression fitting with male/female threaded ends?

A: To install, simply align the fitting with the pipe ends and tighten the threaded connections by hand, then use a wrench for a secure seal. No soldering or special tools are required, making the process quick and clean.Q: What are the main benefits of using these brass compression fittings for pipe connections?

A: The key benefits include high corrosion resistance, ease of installation, strong leak-proof connections, and suitability for a wide range of temperatures and pressures. Their compliance with multiple standards also ensures durability and compatibility.Q: When should these fittings be used in plumbing, gas, or industrial piping applications?

A: These fittings are ideal when you need a reliable connection that will face variable temperatures (from -20C to 150C) and pressures (up to 16 Bar). They are especially useful in installations requiring fast, efficient assembly without heat or solder.Q: Where can you source these compression fittings in India?

A: They are available through various distributors, manufacturers, suppliers, and traders throughout India, ensuring easy and widespread availability for different project scales.Q: What is the process for ensuring a leak-proof connection with these fittings?

A: Ensure that the pipe ends are clean and cut square. Insert the pipe into the fitting, hand-tighten the nuts, then use a wrench to compress the fitting until secure. Proper tightening prevents leaks and maintains performance under pressure.Q: What standards do these compression fittings conform to?

A: They are manufactured in accordance with international standards such as DIN, ASTM, and JIS, guaranteeing product quality, compatibility, and safety for various applications.Q: How does the high corrosion resistance of these fittings benefit long-term usage?

A: Thanks to the brass construction and chrome plating, these fittings resist rust and corrosion even in harsh environments, extending service life and reducing maintenance or replacements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in HDPE Pipe Fittings Category

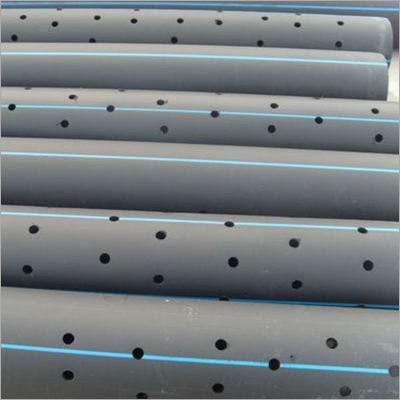

HDPE Perforated Pipes

Price 95 INR / Meter

Minimum Order Quantity : 100

Color : Gray

Material : HDPE

Surface Treatment : Galvanized

Length : Available in 6 m & 12 m or customized

HDPE Perforated Pipe

Price 95 INR / Meter

Minimum Order Quantity : 100

Color : Black (with/without stripes)

Material : High Density Polyethylene (HDPE)

Surface Treatment : Other, Smooth/Plain

Length : Available in coils or straight lengths, typically 6m or customized

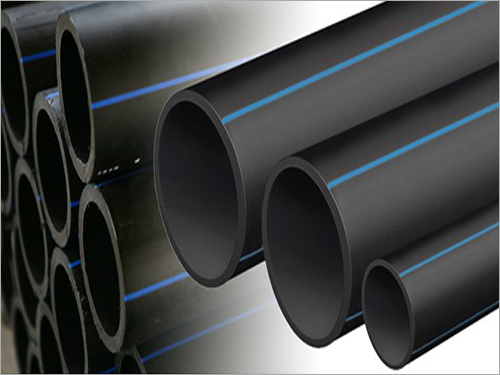

PE Pipe

Price 55 INR / Piece

Minimum Order Quantity : 50 Pieces

Color : Black with Blue Stripes

Material : Polyethylene (PE)

Surface Treatment : Other, Plain / Smooth

Length : 6 m or Customized

HDPE Pipe Stocked

Price 95 INR / Meter

Minimum Order Quantity : 100

Color : Black with Blue Stripes

Material : HighDensity Polyethylene (HDPE)

Surface Treatment : Other, Smooth

Length : 6 meters or Custom Lengths

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free