Plastic Long Pipe

Plastic Long Pipe Specification

- Product Type

- Plastic Long Pipe

- Material

- High Quality Plastic (PVC/UPVC/HDPE)

- Connection

- Plain and Socket End

- Thickness

- Customizable (typically 1 mm to 20 mm)

- Standard

- ISI, ASTM, DIN, BS

- Technics

- Extruded

- Surface Treatment

- Smooth

- Length

- Available in 3 m, 6 m, or as per requirement

- Wall Thickness

- Varies (1 mm to 20 mm)

- Nominal Pressure

- 2.5 to 16 bar

- Color

- White, Grey, Black or as requested

- Temperature Range

- -10°C to +60°C

- Density

- 0.91 to 0.94 g/cm³

- Features

- Corrosion Resistant, Leak Proof, Lightweight, UV Resistant

- Packaging Type

- Wrapped or Loose (customized)

- Application

- Water Supply, Drainage, Irrigation, Industrial Use

- Installation Type

- Above ground and underground

- Flame Retardancy

- Available as per request

- Outer Diameter

- 16 mm to 500 mm

Plastic Long Pipe Trade Information

- Minimum Order Quantity

- 100 Meter

- Main Domestic Market

- South India

About Plastic Long Pipe

Plastic Long Pipe is considered to be perfect for conveying chemicals, water, & gases in various industrial sectors. It is made of strong thermoplastic polymer that shows good resistance to high pressure, heat, and impact. This pipe can easily withstand adverse properties of most chemicals which make it highly demanded in market. It is hassle-free to install and has high durability. This long pipe creates leak-free joints that can be with any type of welding process including butt, socket, or extrusion. Plastic Long Pipe is completely suitable to be used in marine, hydroelectric, chemical, food processing, and agricultural industries.

WE MAINLY DEAL IN SOUTH INDIA

Wide Applicability and Customization

Designed for versatility, these plastic long pipes cater to numerous sectors such as water supply, industrial processes, drainage, and irrigation. With diameter options from 16 mm to 500 mm, customizable lengths and wall thicknesses, and both plain and socket end connections, these pipes can be tailored to exact project specifications, ensuring optimal performance in any setting.

Durable and Reliable Construction

Crafted from high-quality plastics like PVC, UPVC, and HDPE, our pipes are engineered for long-term reliability. They offer excellent corrosion resistance, are leak-proof, lightweight, and withstand a broad temperature range of -10C to +60C. UV resistance and optional flame retardancy further enhance durability, even in demanding outdoor or industrial environments.

Easy Installation and Certified Standards

Installation is convenient and flexible, suitable for both above-ground and underground placements. The smooth extruded finish ensures low friction and easy jointing, while adherence to ISI, ASTM, DIN, and BS standards guarantees consistency and safety. Packaging can be customized, with wrapped or loose options to match transportation and storage needs.

FAQs of Plastic Long Pipe:

Q: How should I install these plastic long pipes for optimal performance?

A: These pipes are suitable for both above-ground and underground installations. It is recommended to follow standard practices for joining, using either plain or socket end connections. Proper bedding and alignment should be ensured, and for underground use, adequate trenching and backfilling are essential to avoid pipe stress and damage.Q: What are the typical applications of these pipes?

A: These pipes are widely used for water supply, drainage systems, agricultural irrigation, and various industrial purposes. Their corrosion resistance, leak-proof design, and customizable features make them an excellent choice for diverse infrastructural needs.Q: When is flame retardant plastic piping recommended?

A: Flame retardant options are advisable in environments with higher fire risk, such as certain industrial or commercial installations. You can request flame retardant properties during your order to ensure the pipes meet specific safety requirements.Q: Where can these pipes be sourced across India?

A: They are available through our network of distributors, manufacturers, suppliers, and traders across India. Customized requirements can be accommodated, and products can be delivered with tailored packaging options to your site or warehouse.Q: What is the manufacturing process and how does it ensure quality?

A: The pipes are produced using an extrusion process, which provides a smooth surface, consistent wall thickness, and uniform diameter. Quality control under ISI, ASTM, DIN, and BS standards ensures each pipe meets stringent performance and safety criteria.Q: Can the pipe thickness and length be customized?

A: Yes, wall thickness can be specified from 1 mm to 20 mm, and standard lengths are 3 m and 6 m, with further customization available upon request to meet project requirements.Q: What are the main benefits of choosing these plastic pipes over traditional materials?

A: They offer superior corrosion resistance, are lightweight for easier handling and installation, and provide leak-proof connections. Additional features like UV and flame resistance (upon request) further enhance their suitability for modern infrastructure.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in HDPE Pipe Fittings Category

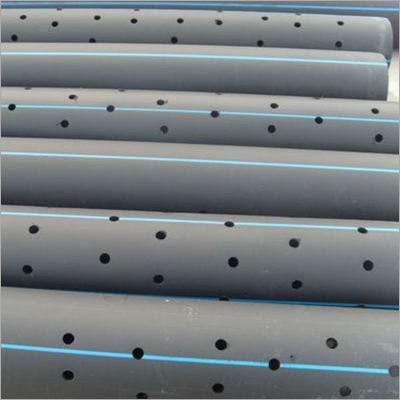

HDPE Perforated Pipes

Price 95 INR / Meter

Minimum Order Quantity : 100

Color : Gray

Surface Treatment : Galvanized

Material : HDPE

Technics : Other, Extruded Molding

Compression Fitting

Price 25 INR / Piece

Minimum Order Quantity : 100 Pieces

Color : Metallic

Surface Treatment : Other, Chrome Plated

Material : Brass

Technics : Forged

HDPE Perforated Pipe

Price 95 INR / Meter

Minimum Order Quantity : 100

Color : Black (with/without stripes)

Surface Treatment : Other, Smooth/Plain

Material : High Density Polyethylene (HDPE)

Technics : Other, Extruded and Perforated

Agricultural HDPE Pipes

Price 95 INR / Meter

Minimum Order Quantity : 100

Color : Black

Surface Treatment : Black Painting

Material : HDPE

Technics : Cold Rolled

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free