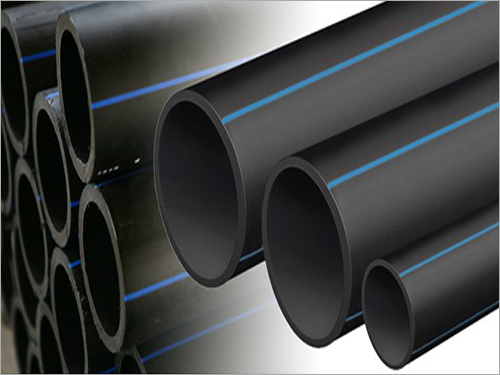

PE Pipe

PE Pipe Specification

- Product Type

- PE Pipe

- Material

- Polyethylene (PE)

- Connection

- Butt Fusion

- Thickness

- Customized as per requirement

- Standard

- IS 4984:1995 / ISO 4427

- Technics

- Extruded

- Surface Treatment

- Plain / Smooth

- Length

- 6 m or Customized

- Wall Thickness

- 2 mm 60 mm

- Nominal Pressure

- 2.5 to 16 bar

- Color

- Black with Blue Stripes

- Temperature Resistance

- Up to 60C

- Corrosion Resistance

- Yes

- Chemical Resistance

- Excellent

- Outer Diameter Range

- 16 mm 1200 mm

- Density

- 0.935 0.960 g/cm

- Lifespan

- Up to 50 Years under Normal Conditions

- Shape

- Round

- Application

- Water Supply, Irrigation, Gas, Sewerage

- Flexibility

- High

- UV Resistance

- Yes

PE Pipe Trade Information

- Minimum Order Quantity

- 50 Pieces

- Main Domestic Market

- South India

About PE Pipe

PE Pipe finds application in plumbing, food processing, chemical, & agricultural industries for conveying of fluids. It is highly appreciated for having low friction, great impact strength, and good ductility. This pipe is known to have seamless surface finish which does not cause any pressure change hence is perfect for both low & high pressure environments. It shows excellent creep under persistent force and has high durability. PE Pipe is also suitable to be used for hydrostatic, marine, and water supply purposes. It is available in different diameters & lengths at competitive rates for our respected clients.

WE MAINLY DEAL IN SOUTH INDIA

Technical Specification

|

Size |

2,1.5,1,3,4 |

|

Unit Length |

6m,12m |

Comprehensive Pipe Solutions

Whether you need PE pipes for water distribution, irrigation, gas conveyance, or sewerage systems, our product range meets stringent Indian and international standards. With advanced extrusion techniques, we ensure precision, durability, and tailor-made solutions. The pipes are available in black with distinctive blue stripes for quick identification and optimal performance in a variety of environments.

Quality and Performance

Made from premium polyethylene with densities ranging from 0.935 to 0.960 g/cm, our pipes demonstrate exceptional chemical, corrosion, and UV resistance. Customized thickness and length ensure compatibility with project requirements, while butt fusion connections provide leak-proof joints. Their flexible nature facilitates easy installation, reducing labour and maintenance costs significantly.

FAQs of PE Pipe:

Q: How are these PE pipes installed, and what connection method is recommended?

A: PE pipes are typically installed using the butt fusion method, which provides strong and leak-proof joints. Installers use specialized equipment to fuse pipe ends, ensuring a seamless connection suitable for water, gas, and sewerage applications.Q: What are the benefits of using PE pipes for water supply and irrigation systems?

A: PE pipes offer high flexibility, excellent chemical and corrosion resistance, and are UV-resistant, ensuring a long lifespan of up to 50 years. Their smooth surface facilitates efficient flow, and they are customizable to specific project requirements, making them ideal for water distribution and irrigation.Q: Where can these PE pipes be used within India?

A: These PE pipes are suitable for a variety of installations across India, including urban and rural water supply, agricultural irrigation, gas transmission lines, and sewerage systems. Their durability and compliance with IS 4984:1995 / ISO 4427 standards make them reliable for diverse environments.Q: What pressure ratings do these PE pipes support, and how is wall thickness determined?

A: The pipes are available with nominal pressure ratings from 2.5 to 16 bar. Wall thickness is customized as per specific project needs and varies between 2 mm to 60 mm, ensuring safety and reliability under various operational pressures.Q: When is it recommended to choose UV-resistant PE pipes?

A: UV-resistant PE pipes should be chosen for installations exposed to direct sunlight or outdoor environments. The UV resistance protects the pipes from photodegradation, maintaining structural integrity and extending service life in such conditions.Q: What is the lifespan of these pipes under normal usage, and how does temperature resistance affect it?

A: Under normal conditions, these PE pipes can last up to 50 years. They are temperature resistant up to 60C, ensuring they maintain their mechanical and chemical properties across a broad range of applications and climatic conditions.Q: How does the extrusion manufacturing process benefit the quality of PE pipes?

A: The extrusion process ensures uniformity and strength throughout the pipe. It produces smooth surfaces, precise dimensions, and consistent wall thickness, which enhances flow efficiency and durability for long-term use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in HDPE Pipe Fittings Category

HDPE Pipe Stocked

Price 95 INR / Meter

Minimum Order Quantity : 100

Material : HighDensity Polyethylene (HDPE)

Color : Black with Blue Stripes

Surface Treatment : Other, Smooth

Length : 6 meters or Custom Lengths

HDPE Water Flow Pipe

Price 95 INR / Meter

Minimum Order Quantity : 100

Material : HighDensity Polyethylene (HDPE)

Color : Black with Blue Stripes

Surface Treatment : Other, Smooth Finish

Length : 6 meter / 12 meter or as per order

HDPE Pipe

Price 110 INR / Meter

Minimum Order Quantity : 100

Material : HDPE

Color : Black

Surface Treatment : Black Painting

Length : 612 Meter (m)

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free